Bolted Ball Space Frame Prefab Steel Structure Barrel Vaults Bolt Ball Metal Space Frame For Coal Storage Shed

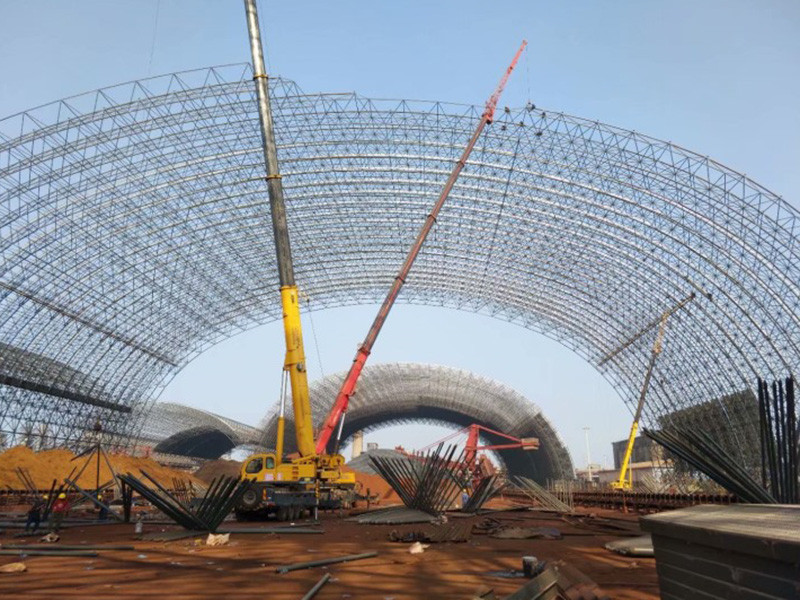

Installation Steps of Longitudinal Space Frame

1) Half arches are pre-assembled on a project

2) Half arches will be joined together to form a rib

3) Half arches are joined together to form a rib

4)Assembly in air

Specification

| Item | Specification | |

| Structural Type | Longitudinal Space Frame Structure | |

| Main Frame | Steel Pipe | Q235 / Q355 Steel |

| Bolt Ball | 45# Steel | |

| Sleeve | Q235 & 45# | |

| High Strength Bolt | 40Cr | |

| Secondary Frame | C-Purlin / Z-Purlin | Q235 / Q345, 250g/m2 galvanized layer, no painting on the surface |

| Enclosure System | Roof Panel | Color Steel Panel / Al-Mg-Mn Panel(The colors&sizes of all panels can be customized as required.) |

| Accessory Structure | Door | Rolling Door / Sliding Door |

| Lighting System | FRP / PC / Window | |

| Ventilation System | Louver / Ventilator | |

| Drainage | Free Drainage | |

| Others | Design Standard | American Standard / European Standard / Chinese Standard |

| Design Lifetime | Above 50 years | |

| Fabrication | ISO Quality Control | |

| Surface Treatment | Blast Cleaning Sa2.5 level, painting or galvanizing(The thickness can be customized as required.) | |

| Packing | Metal Frame for Large Components, Wooden Case or Metal Case for Small Components.Or Bundling | |

| Installation | Installation Guide | |

For Precise Quotation

More details given to us will help work out precise quotation.

|

No. |

Item |

Specification of Project |

Remarks |

|

1 |

Project Location: | _____ Country, Area | |

| Project Size: | L: ___m W: ___m H: ___m / Dia. ___m | ||

| Buidling Shape: | Flat / Dome / Arch / Irregular | ||

|

2 |

Wind Load: | ____kn/m2, ____km/h, ____m/s | |

| Snow Load: | ____kn/m2, ____km/h, ____m/s | ||

| Seismic Load: | ____kn/m2 | ||

| Live Load: | ____kn/m2 | ||

| Dead Load: | ____kn/m2 | ||

|

3 |

Surface Treatment: | Painting / Galvanizing / Powder Coating | |

|

4 |

Roof Materials: | Color Steel Panel / Sandwich Panel / FRP Daylighting Panels / Glass | |

|

5 |

Design Standard: | GB / ASTM / BS / EN / Other |

Dry coal shed is a large warehouse for coal storage in thermal power plants. Due to the requirement of environmental protection and the strict control of construction land, coal bulk must be closed storage and loading, so the construction of dry coal shed has developed vigorously in recent years.

The main function of dry coal shed structure is to put a cap on the coal yard to against rain and wind, which is an energy saving and environmental protection project. The length and width of the structure are determined according to the coal capacity. The height of the structure is determined by the operating requirements of coal heaps and bucket turbines. Therefore, dry coal shed structure is characterized by large span, high height, and wide coverage area.

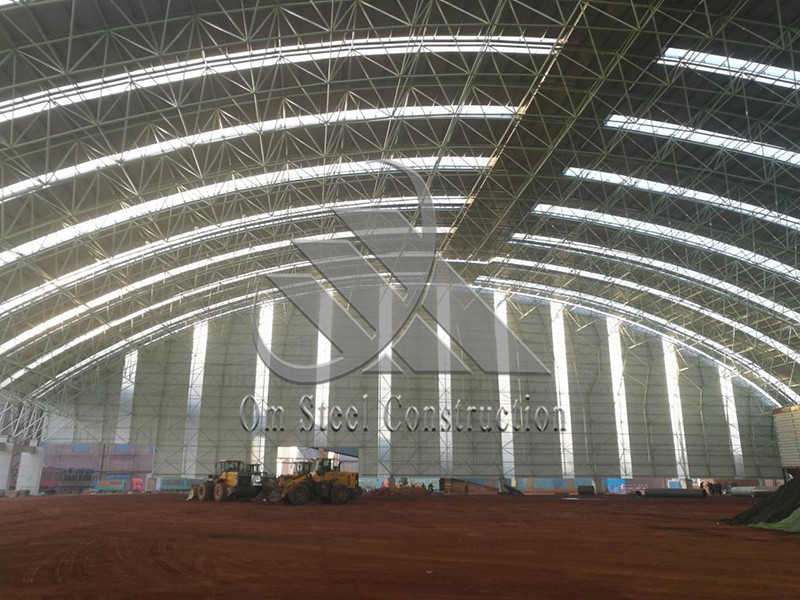

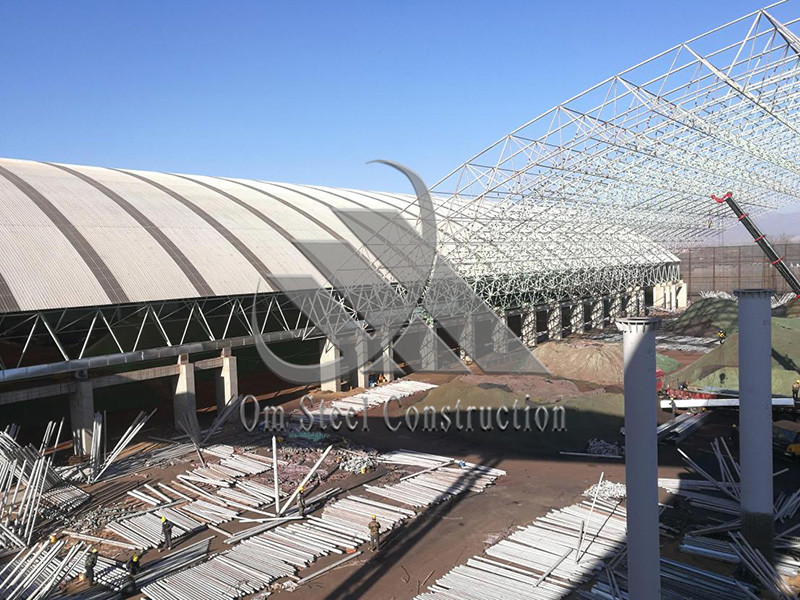

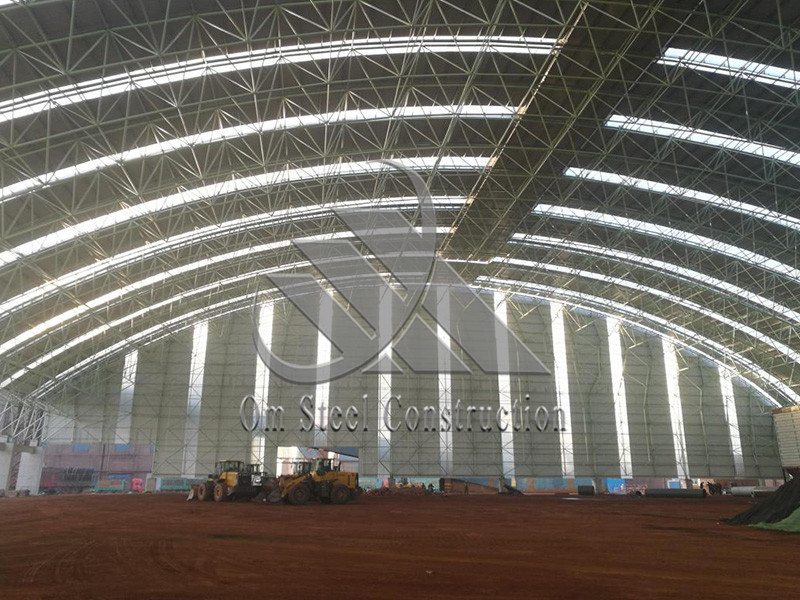

Product Show